Technology Details

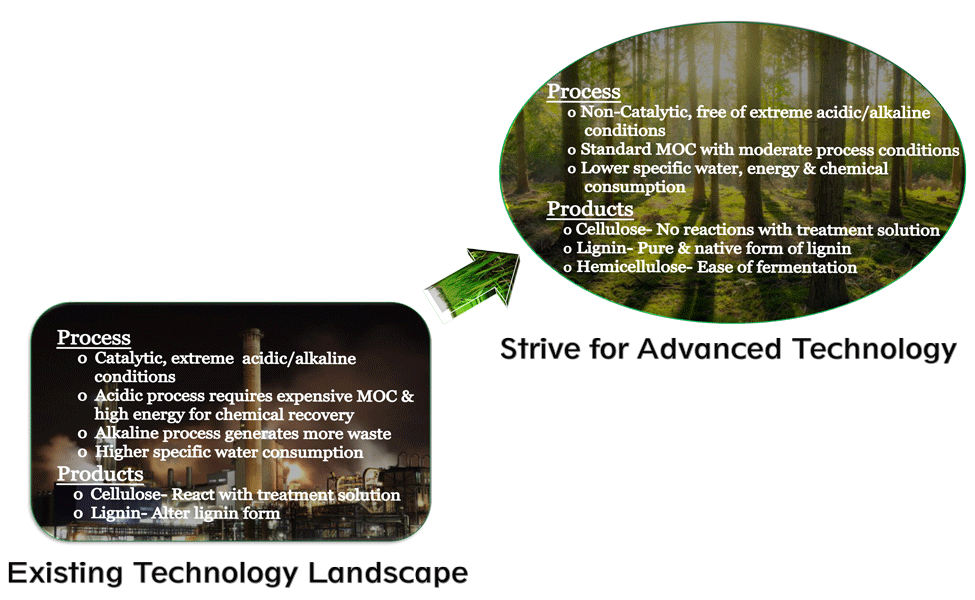

Existing biomass delignification technologies has certain challenges which forms basis for developing advanced technology.

We strive to provide sustainable and economically viable route for new generation bio-refinery with lower capital investment and operating cost through green Lignopura technology.

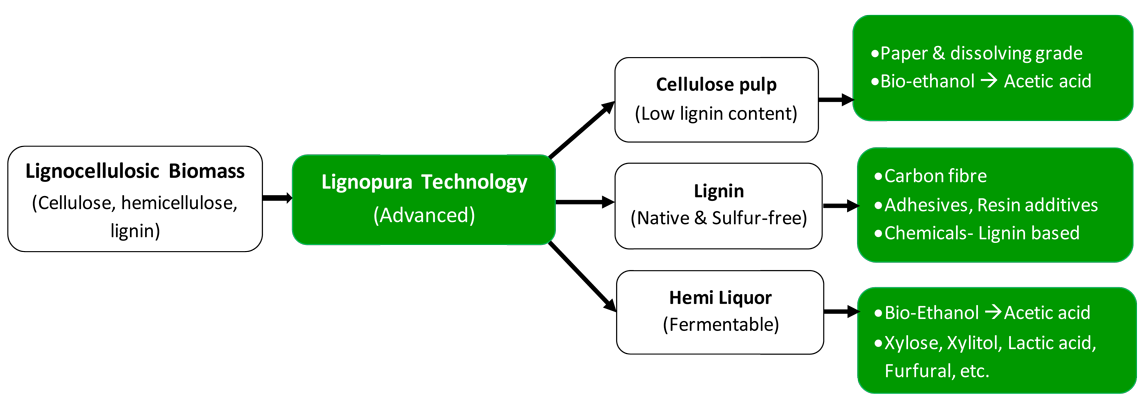

Lignopura technology has a flexibility to treat wider range of lignocellulosic biomass such as hardwood, softwood, agricultural, herbaceous and forestry materials (e.g. bagasse, straw, corn stover, grasses), etc. Lignopura offer efficient and cost effective solution for the production of value added products from wide variety of lignocellulosic biomass.

Lignopura technology is a patented, acid-base free, non-catalytic green technology with recyclable solvents, having highest efficiency to produce sulfur-free, pure and native form of cellulose, lignin and hemicellulose from abundantly available renewable biomass. These purest forms of products are easier to convert into value added chemicals at higher conversion with superior yield.

Lignopura technology helps in overcoming the technological challenge of recalcitrance of renewable lignocellulosic biomass to allow separation of cellulose, lignin and hemicellulose in an effective manner. Separated constitutes, which are sulfur-free, pure and available in their native form, can be further utilized to produce various chemicals with highest conversion efficiency.

High grade cellulose fiber produced through Lignopura technology has been successfully post-treated to make either paper or dissolving grade pulp with highest possible yields as compared to existing processes. High grade cellulose fiber produced through Lignopura technology is also suitable for 2G bio-ethanol and bio-acetic acid production depending upon local requirement and cost-effective utilization routes.